Effective Tail Gas Hydrogenation Catalyst for Improved Emission Control

By:Admin

One of the leading manufacturers in the field of Tail Gas Hydrogenation Catalyst is a company that has been at the forefront of technological innovation in the petrochemical industry for over three decades. With a strong focus on research and development, this company has developed a wide range of catalysts and solutions that have revolutionized the way petrochemical processes are carried out.

The Tail Gas Hydrogenation Catalyst manufactured by this company is known for its high efficiency and reliability. It is designed to operate at high temperatures and pressures, ensuring optimum performance in the most demanding industrial environments. The catalyst is also engineered to have a long lifespan, reducing the need for frequent replacements and maintenance, which helps in reducing operational costs for the end-users.

The company's Tail Gas Hydrogenation Catalyst is a result of years of dedicated research and development. Their team of experts has worked tirelessly to create a catalyst that not only meets but exceeds the industry standards. With a commitment to sustainability, the company has also ensured that their catalysts are environmentally friendly and have a minimal impact on the planet.

In addition to its technical prowess, the company also prides itself on its customer-centric approach. They work closely with their clients to understand their specific requirements and provide tailored solutions that meet their needs. This level of personalized service has earned the company a stellar reputation in the industry, with clients ranging from small businesses to multinational corporations.

To ensure the quality and reliability of their Tail Gas Hydrogenation Catalyst, the company has implemented stringent quality control measures at every stage of the manufacturing process. From raw material selection to final product testing, every aspect is carefully monitored to ensure that only the highest quality catalysts are delivered to the customers.

Furthermore, the company is committed to ongoing research and development to continuously improve its products and stay ahead of the competition. This dedication to innovation has led to the development of cutting-edge technologies and solutions that have helped their clients achieve new levels of efficiency and productivity.

With a global presence, the company has established a strong network of partners and distributors to cater to the needs of the petrochemical industry worldwide. Their Tail Gas Hydrogenation Catalyst has been acclaimed by clients across the globe for its exceptional performance and reliability.

As the petrochemical industry continues to evolve, the demand for efficient and sustainable solutions like the Tail Gas Hydrogenation Catalyst is expected to grow. With its proven track record and unwavering commitment to excellence, the company is well-positioned to meet this growing demand and continue to lead the way in the field of petrochemical catalysts.

Company News & Blog

Top Alumina Carrier for Efficient Material Transportation

Alumina Carrier Unveils Groundbreaking Aluminum Transportation SolutionAlumina Carrier, a leading player in the transportation industry, has recently unveiled a revolutionary new aluminum transportation solution that is set to transform the way aluminum is transported and handled across the globe. The company's innovative approach to aluminum transportation is expected to significantly reduce costs and improve operational efficiency for its clients.The new aluminum transportation solution comes at a time when the aluminum industry is experiencing unprecedented growth, with increasing demand for aluminum products in various sectors including aerospace, automotive, and construction. As a result, the efficient and reliable transportation of aluminum has become more important than ever.Alumina Carrier's new solution has been developed in response to the challenges faced by the aluminum industry, particularly in the transportation and handling of aluminum products. The solution has been designed with a focus on efficiency, reliability, and cost-effectiveness, and is expected to be a game-changer for companies involved in the production and distribution of aluminum products.One of the key features of the new aluminum transportation solution is its advanced technology, which allows for the safe and secure transportation of aluminum products over long distances. The solution includes state-of-the-art transportation containers and handling equipment, as well as advanced tracking and monitoring systems to ensure the safety and security of the aluminum products throughout the transportation process.In addition to its advanced technology, Alumina Carrier's new solution also offers significant cost savings for its clients. The company's streamlined transportation and handling processes are expected to result in lower transportation costs, reduced lead times, and improved overall operational efficiency for clients in the aluminum industry.Furthermore, Alumina Carrier's new aluminum transportation solution is designed to be environmentally friendly, with a focus on reducing carbon emissions and minimizing the environmental impact of aluminum transportation. The company has implemented a number of sustainable practices and initiatives to ensure that its transportation processes are as environmentally friendly as possible.In a statement, the CEO of Alumina Carrier expressed his enthusiasm for the new aluminum transportation solution, stating that it represents a major milestone for the company and the aluminum industry as a whole. He highlighted the company's commitment to innovation and sustainability, and its dedication to providing its clients with the most efficient and cost-effective transportation solutions possible.With its new aluminum transportation solution, Alumina Carrier is well-positioned to meet the growing demand for efficient and reliable transportation of aluminum products. The company's innovative approach to aluminum transportation is expected to set a new standard for the industry, and to provide its clients with a competitive edge in an increasingly demanding market.As the aluminum industry continues to expand, the efficient and reliable transportation of aluminum products will be crucial for companies looking to stay ahead of the competition. With its groundbreaking new solution, Alumina Carrier is poised to lead the way in aluminum transportation and to help shape the future of the industry.In conclusion, Alumina Carrier's new aluminum transportation solution represents a significant advancement for the aluminum industry, offering a range of benefits including improved efficiency, cost savings, and environmental sustainability. The company's innovative approach to aluminum transportation is expected to have a lasting impact on the industry, providing its clients with a competitive advantage in a rapidly evolving market.

Understanding Alumina: Properties, Uses, and Characteristics

Alumina, also known as aluminum oxide or Al2O3, is a chemical compound with a melting point of approximately 2,000°C and a specific gravity of around 4.0. It is an odorless, tasteless, and non-toxic powder that is white to off-white in color. Alumina is a highly versatile material with a wide range of applications spanning various industries.One of the most important uses of alumina is in the production of aluminum metal. Alumina is refined from bauxite ore through a process called the Bayer process. In this process, the bauxite is crushed, dried, and heated to remove any water and impurities. Then, the alumina is extracted from the resulting solution and refined further to produce high-purity alumina.In addition to its use in aluminum manufacturing, alumina is used in a variety of other applications. For example, it is used as a catalyst in the petrochemical industry to convert crude oil into usable products. It is also used as a refractory material in high-temperature applications such as kilns, furnaces, and blast furnaces.Gamma alumina, in particular, is a highly crystalline form of alumina that is often used as a catalyst support. It has a large surface area and pore volume, which makes it ideal for catalytic reactions. Gamma alumina is also used as a support material in the manufacturing of other chemicals such as ethanol, ethylene, and propylene.Other applications of alumina include the production of abrasives such as sandpaper, grinding wheels, and polishing compounds. It is also used as a filler in plastics, ceramics, and rubber. Alumina is even used as a dental material in the form of dental implants and crowns.Overall, alumina is a highly versatile material with a wide range of applications in various industries. Its properties such as high melting point, hardness, and chemical stability make it a valuable material for many applications. Gamma alumina, in particular, has unique properties that make it ideal for use as a catalyst support. As technology continues to advance, it is likely that alumina will continue to play an important role in many industries.

Diverse Applications of Microspheres: Lightweight, High Strength Ceramic Spheres Enhancing Rheology and Thermal Insulation

Title: Alumina Microspheres: Revolutionizing Various IndustriesIntroduction to Alumina MicrospheresAlumina microspheres, also known as cenospheres, are lightweight and hollow ceramic spheres with a wide range of applications. Composed primarily of silica and alumina and sized below 300 microns, these microscopic spheres possess unique properties that make them highly versatile in several industries.Applications of Alumina Microspheres1. Construction Industry: A. Cementitious Systems: Alumina microspheres are used in cementitious systems to modify rheology, reduce weight and shrinkage, and enhance thermal insulation. They improve the overall performance of cement-based products such as sealants, putties, dry-mix adhesives, mortars, jointing compounds, and oil-well cements. B. Refractories: Specialized grades of alumina microspheres are employed in refractory applications. They enhance the thermal insulation properties of refractory materials utilized in high-temperature environments, such as furnaces, kilns, and reactors. C. Surface Coatings: Alumina microspheres find their usage in surface coatings, where they improve the durability, strength, and impact resistance of the coatings.2. Polymer Industry: Alumina microspheres are incorporated into various polymer applications to enhance their mechanical properties and reduce resin demand. A. Plastics and Gel-coats: They are extensively used in the plastics and gel-coats industry, including polyurethane, latex emulsions, PVC, epoxy resins, and unsaturated polyester resins. The addition of alumina microspheres not only strengthens the materials but also improves their impact resistance. B. Composite Materials: Alumina microspheres aid in reducing the amount of resin required in composite materials. This results in lighter and more cost-effective composites without compromising the strength and impact resistance of the final product.Advantages and Properties of Alumina Microspheres1. Low Bulk Density: Alumina microspheres possess low bulk density, which makes them ideal for applications where weight reduction is a requirement. This property is highly advantageous in the construction industry, where lightweight materials are desired without compromising structural integrity.2. High Strength: Despite their lightweight nature, alumina microspheres exhibit high strength. This property enhances the overall durability and impact resistance of the materials they are incorporated into, making them an excellent choice for various industries.3. Uniform Sphericity: The uniform sphericity of alumina microspheres ensures consistent performance and ease of incorporation into different applications. Their spherical shape facilitates even distribution within matrices, resulting in enhanced mechanical properties and consistent end products.4. Thermal Insulation: Alumina microspheres improve thermal insulation due to their hollow structure, which reduces heat transfer. This property finds significant use in refractories and cementitious systems, where thermal insulation is crucial for energy efficiency.ConclusionAlumina microspheres have revolutionized the construction and polymer industries with their unique properties and diverse range of applications. With their low bulk density, high strength, uniform sphericity, and thermal insulation capabilities, these microscopic spheres have proven to be essential additives in cementitious systems, refractories, surface coatings, and polymer applications.Whether it is modifying rheology, reducing weight and shrinkage, improving impact resistance, enhancing thermal insulation, or reducing resin demand, alumina microspheres offer tangible benefits to various industries. As innovation continues to drive the development of new materials and technologies, the use of alumina microspheres is expected to grow further, enabling the creation of lighter, stronger, and more efficient products.

What is Dechlorination? Definition and Meaning in Medical Dictionary

Dechlorination: A Vital Step in Water TreatmentDo you know that almost all tap water has a small amount of chlorine in it? Chlorine is necessary to kill harmful bacteria and other contaminants that may be present in water. However, while chlorine is an effective disinfectant, it can also have undesired effects, such as the unpleasant taste and odor of water. This is where dechlorination comes in.Dechlorination is the process of removing chlorine from water. It is typically done by using a dechlorination agent, which neutralizes the chlorine and converts it into chloride. Dechlorination is a crucial step in water treatment, especially for processes that follow disinfection, such as fish farming and aquariums.Dechlorination agents are typically made up of sodium bisulfite or sodium sulfite. These chemicals are added to the water to neutralize excess chlorine, rendering it safe for use. Dechlorination agents are commonly available in liquid and powder form. They are easy to use and very effective in removing chlorine from water.One of the most common uses of dechlorination agents is in swimming pools. Chlorine is used in swimming pools to kill off bacteria and other unwanted contaminants. However, chlorinated water can be harsh on the skin and can cause irritation to swimmers. This is where dechlorination comes in. By using a dechlorination agent, pool water can be converted into safe, non-irritating, and odorless water.Dechlorination agents are also commonly used in the food and beverage industry. Chlorine is often used to disinfect equipment and surfaces where food and beverages are processed and prepared. However, excess chlorine can lead to off-tastes and odors in the final product. Dechlorination agents are used to ensure that the water used in the production process is safe and of high quality.In conclusion, dechlorination is an essential step in the water treatment process. It helps to remove excess chlorine from water, making it safe and pleasant to use. Dechlorination agents are effective, safe, and readily available, and can be used for a wide range of applications, including swimming pools, food and beverage production, and aquariums. If you're looking for a way to make your water safer and better-tasting, consider using a dechlorination agent.

Advanced Isomerization Catalyst Technology for Enhanced Chemical Conversion

Isomerization Catalyst Market Trends and Growth OpportunitiesIsomerization Catalyst Market size is likely to expand at a significant CAGR from 2022 to 2028. The Isomerization Catalyst is a key component used in the petroleum refining industry for the production of high octane gasoline. It is an important process used to convert straight-chain hydrocarbons into branched-chain hydrocarbons, which helps to improve the octane number of gasoline and increase its efficiency in engines.The global Isomerization Catalyst market is witnessing a steady growth due to the increasing demand for high octane gasoline, stringent environmental regulations, and the growing focus on sustainable energy solutions. The market is also driven by the growing investments in the oil and gas industry and the rising demand for transportation fuels in emerging economies.The Isomerization Catalyst market is segmented based on type, application, and region. Based on type, the market is categorized into noble metal catalysts, base metal catalysts, and others. The noble metal catalysts segment is expected to hold a significant share of the market due to its high efficiency and durability. In terms of application, the market is divided into gasoline production and others. The gasoline production segment is anticipated to lead the market owing to the increasing demand for high octane gasoline in the automotive industry.Key players in the Isomerization Catalyst market include {}, {}, {} and {}. These companies are focusing on research and development activities to develop innovative and sustainable solutions to meet the growing demand for isomerization catalysts. They are also adopting strategies such as mergers and acquisitions, partnerships, and collaborations to expand their market presence and strengthen their product portfolio.One of the leading companies in the Isomerization Catalyst market is {}. They are a global leader in providing advanced catalyst solutions for the petroleum refining industry. The company has a strong focus on research and development to develop catalysts that offer high activity, selectivity, and stability for isomerization processes. They also have a strong presence in the key regions such as North America, Europe, and Asia-Pacific, which allows them to cater to the growing demand for isomerization catalysts in these regions.Another key player in the Isomerization Catalyst market is {}. They are known for their high-performance catalysts that are designed to meet the specific needs of the petroleum refining industry. The company has a strong focus on sustainability and is committed to developing catalysts that are environmentally friendly and energy-efficient. They also have a wide range of products and services to cater to the diverse needs of their customers.The Isomerization Catalyst market is witnessing significant growth opportunities in the Asia-Pacific region due to the growing demand for transportation fuels and the increasing investments in the oil and gas industry. The region is also experiencing rapid industrialization and urbanization, which is fueling the demand for high octane gasoline.In conclusion, the Isomerization Catalyst market is poised for significant growth in the coming years due to the increasing demand for high octane gasoline, the rising investments in the oil and gas industry, and the growing focus on sustainable energy solutions. Key players in the market are focusing on research and development activities to develop innovative and sustainable solutions to meet the growing demand for isomerization catalysts. The Asia-Pacific region is expected to offer lucrative growth opportunities for the market due to the growing demand for transportation fuels and the rapid industrialization and urbanization in the region.

Highly Effective Al2o3 Catalyst for Various Chemical Reactions

Al2O3 Catalyst: The Key to Sustainable and Efficient Chemical ProcessesIn the world of chemical manufacturing, catalysts play a crucial role in enabling sustainable and efficient processes. Among the various types of catalysts, Al2O3 catalysts have gained immense popularity for their ability to drive a wide range of chemical reactions with high selectivity and efficiency. Today, we will delve into the world of Al2O3 catalysts and explore their significance in the chemical industry.Before we dive into the specifics of Al2O3 catalysts, it is essential to understand the company behind these innovative catalysts. The company, which specializes in the development and production of advanced catalyst materials, has been at the forefront of catalysis technology for over two decades. With a strong focus on innovation and sustainability, the company has continuously pushed the boundaries of catalytic science, leading to the development of cutting-edge catalysts that address the evolving needs of the chemical industry.Al2O3, also known as aluminum oxide, serves as the backbone of the company’s catalyst technology. This versatile material exhibits exceptional thermal stability, high surface area, and acidic or basic properties, making it an ideal candidate for a wide range of catalytic applications. The company has leveraged the unique properties of Al2O3 to develop a portfolio of catalysts that cater to diverse chemical processes, including but not limited to, petrochemical refining, environmental remediation, and specialty chemical synthesis.One of the key strengths of Al2O3 catalysts lies in their ability to facilitate various catalytic reactions with high efficiency and selectivity. Whether it is the conversion of feedstocks into valuable products or the removal of harmful pollutants from industrial effluents, Al2O3 catalysts have demonstrated exceptional performance in driving these reactions while minimizing unwanted by-products. This results in significant cost savings for chemical manufacturers and reduces the environmental footprint of their processes.Furthermore, the company’s Al2O3 catalysts are designed to withstand the extreme operating conditions encountered in many chemical processes. With a focus on durability and longevity, these catalysts offer superior stability under high temperatures, pressures, and corrosive environments, ensuring prolonged catalyst life and consistent performance. This not only translates to cost-effective operations for the end-users but also aligns with the company’s commitment to sustainable and responsible manufacturing practices.In addition to their performance and durability, Al2O3 catalysts from the company are also notable for their versatility. The company offers a range of tailored catalyst formulations based on Al2O3 that are specifically designed to address the unique requirements of different chemical processes. Whether it is a fluidized bed reactor for catalytic cracking or a fixed-bed system for selective oxidation, the company’s Al2O3 catalysts can be customized to deliver optimal performance, thereby maximizing process efficiency and product quality.Looking ahead, the company continues to invest in research and development to further enhance the capabilities of Al2O3 catalysts. With a focus on leveraging advanced materials science and process engineering, the company aims to develop the next generation of Al2O3 catalysts that push the boundaries of catalytic performance and sustainability. These efforts are driven by the company's vision to be a leading provider of advanced catalyst solutions that enable the chemical industry to meet the challenges of tomorrow.In conclusion, Al2O3 catalysts have emerged as vital enablers of sustainable and efficient chemical processes, thanks to their exceptional performance, durability, and versatility. With the company's relentless commitment to innovation and sustainability, Al2O3 catalysts are set to play an even more significant role in shaping the future of the chemical industry. As the demand for cleaner, more sustainable chemical processes continues to grow, Al2O3 catalysts will undoubtedly be at the forefront of this transformative journey.

Alumina Plant Announces New Production Capabilities

[Company Name] is excited to announce the launch of its newest product, Gama Alumina, designed to meet the growing demands of the aluminum industry. As a leading supplier of industrial materials, [Company Name] is dedicated to providing high-quality products that support various manufacturing processes.Gama Alumina is a versatile material that offers exceptional performance and reliability in aluminum production. It is produced using advanced technology and high-quality raw materials, ensuring consistency and purity in every batch. With its superior characteristics, Gama Alumina is poised to make a significant impact on the aluminum industry, driving efficiency and innovation in manufacturing processes.One of the key advantages of Gama Alumina is its high chemical purity, which plays a critical role in the production of high-quality aluminum. The material's low impurity levels contribute to improved smelting efficiency and reduced environmental impact, making it an attractive choice for aluminum manufacturers seeking sustainable solutions. In addition, Gama Alumina boasts excellent thermal stability, allowing for consistent performance in high-temperature environments, such as aluminum smelting operations."We are thrilled to introduce Gama Alumina to the market," said [Spokesperson's Name], CEO of [Company Name]. "This cutting-edge material represents our commitment to delivering innovative solutions that empower our customers to achieve their production goals. Gama Alumina is the result of extensive research and development, and we are confident that it will set new standards for excellence in the aluminum industry."In line with [Company Name]'s dedication to customer satisfaction, Gama Alumina is available in various grades and particle sizes, allowing for customization based on specific application requirements. Whether it's for primary aluminum production or secondary aluminum processing, customers can rely on Gama Alumina to deliver consistent performance and exceptional value.As part of its commitment to quality and reliability, [Company Name] conducts rigorous quality control measures to ensure that Gama Alumina meets the highest standards. The material is thoroughly tested for chemical composition, particle size distribution, and other key parameters to guarantee its performance in real-world applications. This stringent quality assurance process underscores [Company Name]'s unwavering dedication to delivering products that instill confidence and trust in its customers.The introduction of Gama Alumina further solidifies [Company Name]'s position as a leading provider of industrial materials, with a focus on driving progress and innovation in key sectors such as aluminum production. By leveraging its expertise and resources, [Company Name] continues to expand its product portfolio to address the evolving needs of its customers and the broader industry.In addition to its technical capabilities, Gama Alumina is backed by [Company Name]'s exceptional customer support and technical expertise. With a team of knowledgeable professionals, [Company Name] is well-equipped to assist customers in integrating Gama Alumina into their processes, providing guidance and resources to optimize performance and efficiency.As [Company Name] prepares for the commercial release of Gama Alumina, it anticipates a positive response from aluminum manufacturers seeking advanced materials that can enhance their operations. With its remarkable attributes and [Company Name]'s unwavering commitment to excellence, Gama Alumina is poised to make a significant impact on the aluminum industry, driving progress and innovation in the years to come.In conclusion, the launch of Gama Alumina represents a major milestone for [Company Name] and the aluminum industry as a whole. With its exceptional performance, versatility, and reliability, Gama Alumina is poised to elevate manufacturing processes and set new standards for excellence in aluminum production. As [Company Name] continues to lead the way in delivering advanced materials and solutions, Gama Alumina stands as a testament to its dedication to innovation and customer success.

Innovative Catalyst Solution Making Waves in Industry News

Clariant Catalyst is a leading company in the field of catalysts, with a strong focus on research and development. With a wide range of products and services, the company is committed to providing innovative solutions that meet the needs of its customers. Clariant Catalyst's portfolio includes a variety of catalysts for different applications, such as petrochemicals, chemicals, and plastics. The company's products are designed to improve efficiency, reduce emissions, and enhance the overall performance of industrial processes.One of the company's key strengths is its focus on sustainability. Clariant Catalyst is dedicated to developing solutions that contribute to a more sustainable future. The company's products are designed to help its customers reduce their environmental impact and improve their overall sustainability performance.In addition to its strong focus on sustainability, Clariant Catalyst is also committed to innovation. The company invests heavily in research and development, and is constantly working on new technologies and solutions to meet the evolving needs of its customers.Clariant Catalyst also places a strong emphasis on customer relationships. The company works closely with its customers to understand their specific needs and develop tailored solutions that address their unique challenges. This customer-centric approach has helped Clariant Catalyst build strong, long-lasting relationships with its clients.Overall, Clariant Catalyst is a leading company in the field of catalysts, with a strong focus on sustainability, innovation, and customer relationships. The company's commitment to providing innovative solutions that meet the needs of its customers sets it apart in the market.The company's recent innovation is the development of a new catalyst that has the potential to revolutionize the petrochemical industry. This new catalyst has been designed to significantly improve the efficiency of petrochemical processes, while also reducing emissions and enhancing sustainability performance.The development of this new catalyst is the result of years of research and development by Clariant Catalyst's team of experts. The company's investment in innovation has enabled it to develop a groundbreaking solution that has the potential to make a significant impact on the petrochemical industry.In addition to its environmental benefits, the new catalyst is also expected to deliver cost savings for petrochemical producers. By improving process efficiency and reducing energy consumption, the new catalyst has the potential to deliver significant financial benefits for its users.Clariant Catalyst's commitment to sustainability is further underscored by the fact that the new catalyst is designed to be highly recyclable. This not only aligns with the company's focus on environmental responsibility, but also helps its customers reduce waste and improve their overall sustainability performance.The new catalyst is currently undergoing field trials, and early results have been very promising. If successful, this new innovation has the potential to revolutionize the petrochemical industry and set a new standard for sustainability and efficiency.Overall, Clariant Catalyst's recent innovation highlights the company's strong commitment to sustainability, innovation, and customer value. The development of this groundbreaking new catalyst underscores the company's position as a leader in the field of catalysts, and its dedication to providing innovative solutions that meet the evolving needs of its customers.

Alumina production forecasted to increase in the coming months

Gama Alumina, a global leader in the production of high-quality alumina products, has been making waves in the industry with its latest technological advancements and sustainable business practices. With a focus on innovation and excellence, the company has set new standards for alumina production and continues to push the boundaries of what is possible in the industry.Gama Alumina's dedication to research and development has led to the creation of cutting-edge production processes that have revolutionized the way alumina is produced. By investing in state-of-the-art equipment and continually improving their techniques, the company has been able to consistently deliver products of exceptional quality to their customers around the world.In addition to their commitment to innovation, Gama Alumina is also deeply committed to sustainability and environmental responsibility. The company has implemented a range of initiatives to minimize their environmental impact, including reducing water and energy consumption, minimizing waste, and implementing environmentally-friendly practices throughout their production process. By taking these steps, Gama Alumina is not only reducing their own carbon footprint but also setting an example for the entire industry to follow.Furthermore, Gama Alumina has a strong focus on corporate social responsibility, working closely with local communities to support education, healthcare, and economic development initiatives. This commitment to giving back has helped strengthen the communities in which the company operates and has earned them a reputation as a responsible and caring corporate citizen.With a track record of success and a dedication to excellence, Gama Alumina is well-positioned to continue leading the industry for years to come. The company's forward-thinking approach and commitment to sustainability will undoubtedly set them apart in an increasingly competitive market.In addition to its industry-leading practices, Gama Alumina also offers a wide range of high-quality alumina products to meet the diverse needs of its customers. From high-purity alumina for advanced ceramics to smelter-grade alumina for the production of aluminum, the company's product portfolio is comprehensive and versatile.One of Gama Alumina's flagship products is its high-purity alumina, which is used in a variety of demanding applications including LED lighting, lithium-ion batteries, and semiconductor production. With its exceptional purity and performance, Gama Alumina's high-purity alumina is considered to be the gold standard in the industry and is trusted by customers for its reliability and consistency.In addition to high-purity alumina, the company also produces a range of smelter-grade alumina products that are essential for the production of aluminum. Gama Alumina's smelter-grade alumina is known for its exceptional quality and consistency, making it the go-to choice for aluminum producers around the world.Gama Alumina's commitment to excellence, innovation, and sustainability has cemented its position as a leader in the global alumina industry. With a track record of success and a dedication to serving their customers' needs, the company is well-positioned to continue driving the industry forward and setting new standards for years to come. With a strong focus on research and development, sustainability, and corporate social responsibility, Gama Alumina is not only a powerhouse in the industry, but also a responsible and caring corporate citizen. As the global demand for high-quality alumina products continues to grow, Gama Alumina is poised to meet this demand and exceed expectations with its exceptional products and industry-leading practices.

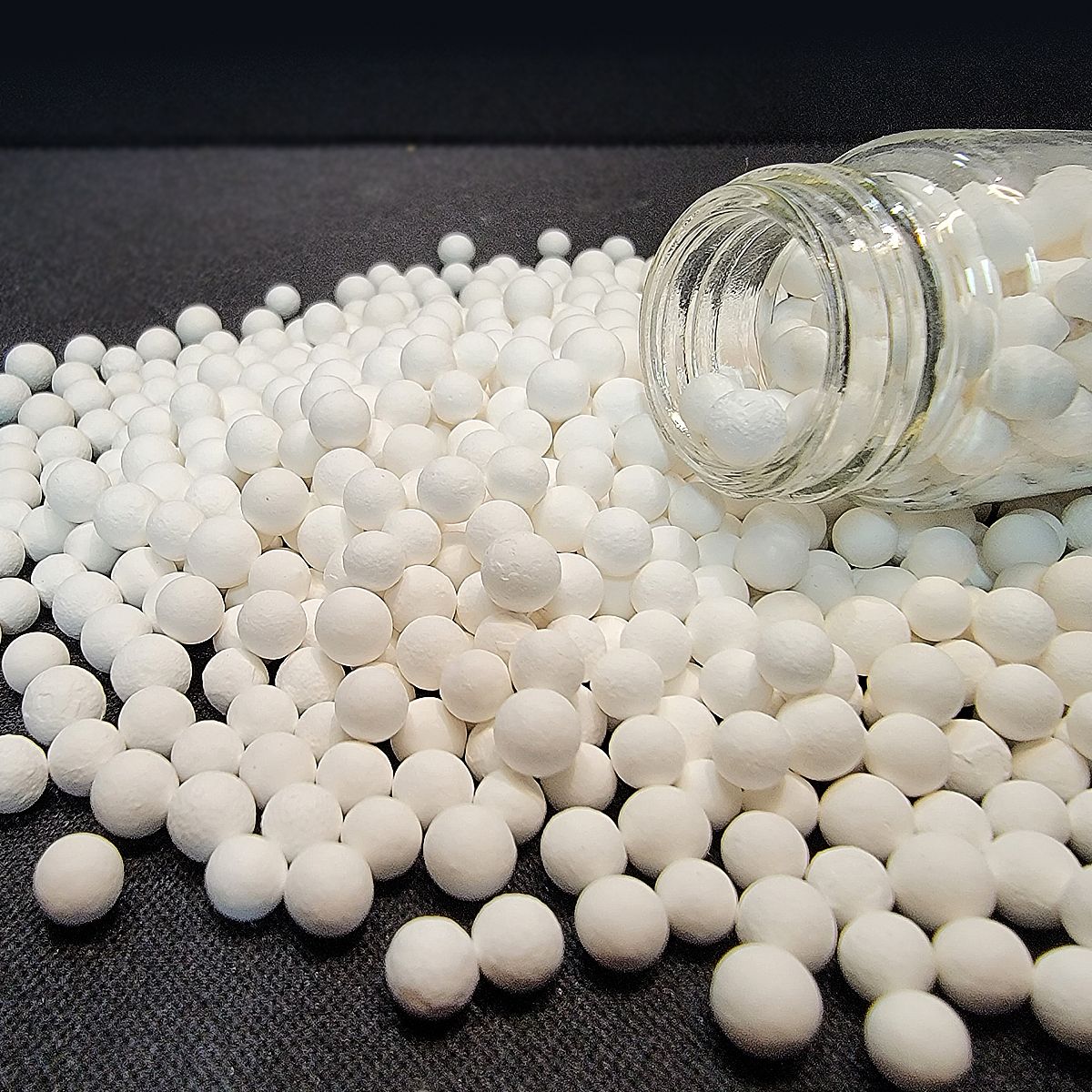

High-Quality Alumina Desiccant for Moisture Control

Alumina Desiccant: The Ultimate Solution for Moisture ControlIn order to understand the significance and demand for Alumina Desiccant, it is crucial to first understand the issues that arise from moisture and humidity in various industries. One of the most significant problems that organizations across different sectors face is moisture damage, which can lead to substantial financial losses and damage to their products. To solve this issue, the use of desiccants has become increasingly popular. These materials are used to absorb moisture, keeping the environment dry and free from potential damage. Among the various desiccants available in the market, Alumina Desiccant has emerged as a leading solution due to its unparalleled efficiency and reliability.{Company Name} is a renowned provider of Alumina Desiccant, offering a wide range of solutions to meet the moisture control needs of various industries. With a strong commitment to quality and customer satisfaction, {Company Name} has established itself as a trusted partner for businesses seeking effective moisture control solutions.One of the key features of {Company Name}'s Alumina Desiccant is its exceptional moisture absorption capacity. This desiccant can effectively reduce the humidity levels in a controlled environment, preventing any moisture-related damage to the products. Moreover, it offers a highly cost-effective solution, as it can be used for extended periods without needing replacement, resulting in significant cost savings for businesses.Another important aspect of {Company Name}'s Alumina Desiccant is its versatility. It can be used in a wide range of applications, including pharmaceuticals, electronics, food and beverage, and many others. This versatility makes it an ideal choice for businesses operating in different industries, providing them with a reliable solution for moisture control.In addition to its efficiency and versatility, {Company Name}'s Alumina Desiccant is also known for its environmental friendliness. It is a non-toxic and chemically inert material, making it safe for use in various applications. Furthermore, it can be easily disposed of, without posing any harm to the environment, making it an ideal choice for businesses that prioritize sustainability and environmental responsibility.{Company Name} takes pride in its commitment to innovation and continuous improvement. The company invests in research and development to further enhance the performance of its Alumina Desiccant, ensuring that it meets the evolving needs of its customers. This dedication to innovation has allowed {Company Name} to stay ahead of the curve and maintain its position as a leading provider of moisture control solutions.Furthermore, {Company Name} also offers customized solutions to meet the specific requirements of its customers. Whether it is a unique application or a specific set of environmental conditions, the company works closely with its clients to develop tailored solutions that address their individual needs. This personalized approach has earned {Company Name} a reputation for excellence and reliability in the industry.In conclusion, Alumina Desiccant is a crucial solution for businesses seeking effective moisture control to protect their products from damage. {Company Name} has established itself as a leading provider of Alumina Desiccant, offering unmatched efficiency, versatility, and environmental friendliness. With a commitment to innovation and customer satisfaction, {Company Name} is poised to continue its contribution to the success of businesses across various industries.